pipe fittings, valves, aseptic diaphragm valves, aseptic tank bottom valves and other high-end products

pipe fittings, valves, aseptic diaphragm valves, aseptic tank bottom valves and other high-end products

applicable industries:air separation equipment,lng storage and transportation equipment,aviation,petrochemical and pharmaceutical

equipment.

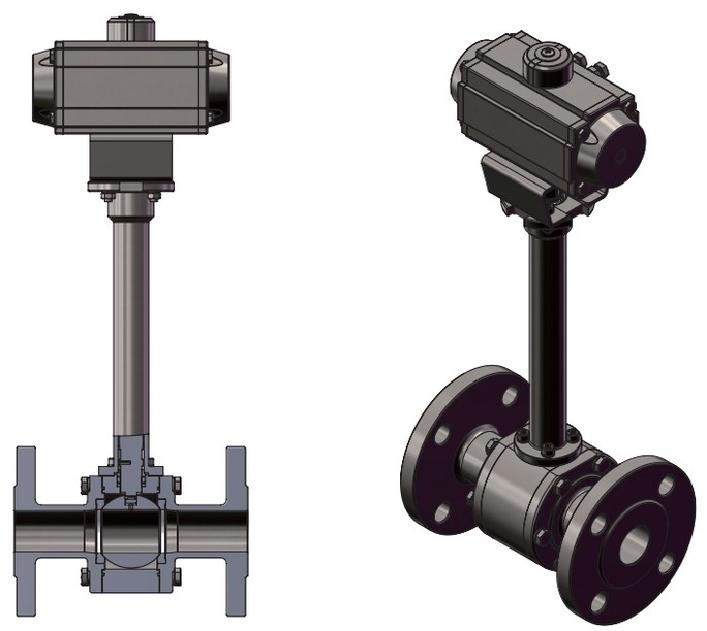

cryogenic ball valve ,also known as liquid nitrogen stainless steel ball valve or liquid nitrogen cryogenic ball valve ,is used to open and

shut the flow of cryogenic media.it can be applied on ethylene/lng facilities,lpg/lng storage tanks,receiving base and satellite station,

air separation equipment,petrochemical exhaust gas separation equipment,cryogenic liquid oxygen/liquid nitrogen/liqiud argon/carbon dioxide

storage tanks,tank cars,and psa oxygen plants.

1.manually pressurized materials can withstand the expansion and contraction caused by the temperature change of media,and the structure of the sealing part will not be deformed when the temperature changes.if the valve is to be used in the working conditions below-100℃,the valve parts should be cryogenically treated before finishing,that is,the parts should be immersed in a liquid nitrogen box for cooling.when the temperature of the parts reaches-192℃,they should be maintained at that temperature for 1-2 hours,and then taken out to ambient environment.repeat for 2 cycles.

2.the bonnet adopts a long structure with a purpose of keeping the stuffing box in position far away from the low temperature and thus protectingits function andensuring the sealing effect of the packing.meanwhile,it can be wrapped with cold insulation materials to prevent cryogenic energy loss.different lengths can be applied according to the operation temperature and the thickness of cold insulation materials.when the packing sealing performance is reduced,grease can be added from the center of the stuffing box to form an oil seal layer,which can reduce the pressure difference of the stuffing box and improve the sealing performance.

3.if the operation temperature is below-100℃,the stem shall be coated with chrome or treated with nitrogen to further harden the surface and improve the sealing performance of packing.

4.the cryogenic ball valve has a structure to prevent abnormal pressure increase.in the event ofmedium vaporization,its volume expands rapidly, and the pressure will increase abnormally.when the pressure in the valve cavity increases,to ensure safe usage,the cavity will be connected with pipes;or a pressure relief valve will be installed with the valve.

5.the washers incryogenic ball valves can stay reliable and resilient at normal/low temperaturesas well as during temperature changes.

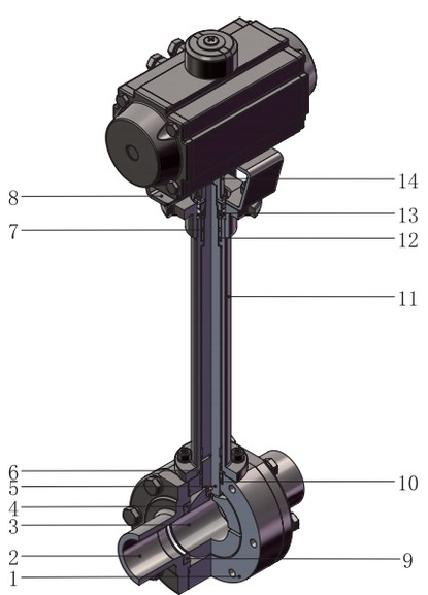

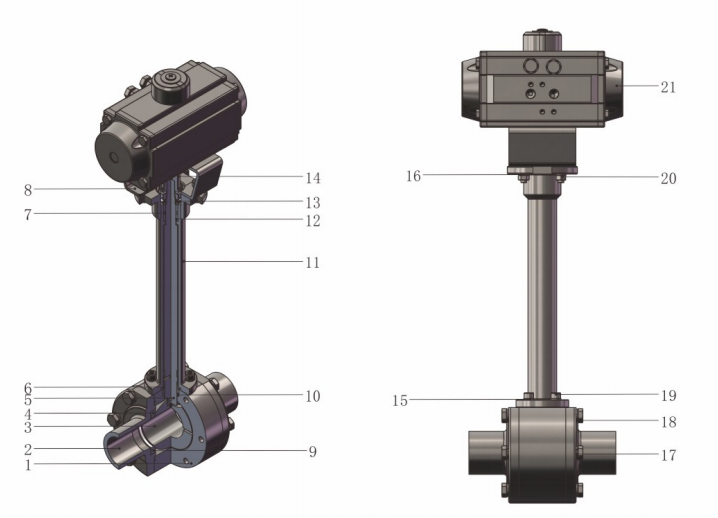

|

number |

name |

material |

|

1 |

valve body |

ss/hc/t |

|

2 |

valve cap |

ss/hc/ti |

|

3 |

ball core |

ss/hc/ti |

|

4 |

body sea |

ptfe |

|

5 |

connecting shaft |

ss/hc/ti |

|

6 |

bushing |

ptfe |

|

7 |

pressing ring |

304 |

|

8 |

bracket |

304 |

|

9 |

cap seal |

ptfe |

|

10 |

v-seal components |

ptfe |

|

11 |

extension bracket |

ss/hc/ti |

|

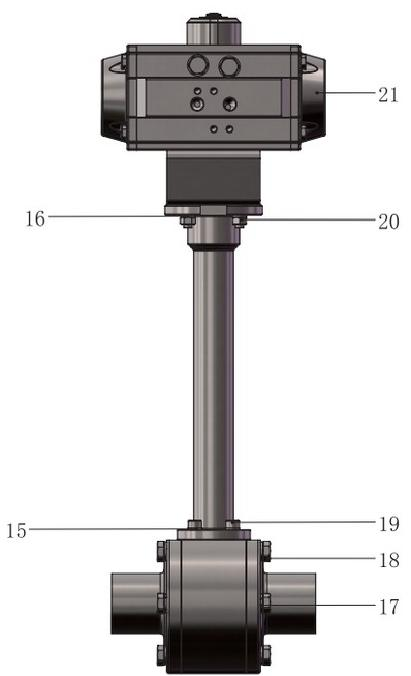

number |

name |

material |

|

12 |

v-seal components |

ptfe |

|

13 |

belleville spring |

301 |

|

14 |

connecting sleeve |

304 |

|

15 |

spring washer |

304 |

|

16 |

spring washer |

304 |

|

17 |

spring washer |

304 |

|

18 |

screw |

304 |

|

19 |

screw |

304 |

|

20 |

nut |

304 |

|

21 |

air diaphragm actuator |

304 |

note:the material of each part may be different under different working conditions.the specific materialshall prevail.

|

technical parameters: |

|

|

aatugtio |

stainless steel stem,turbine stem,aluminum pneumatic actuator (single/double acting),electric actuator |

|

size |

dn15-dn80 |

|

body |

3-pcs forged body |

|

fluid-contacting surface |

ss/hc |

|

non-fluid-contacting surface |

304 |

|

connection |

welded,flange |

|

operation pressure |

pn1.6~6.4mpa |

|

operation temperature |

-196℃~ 120℃ |

|

seal materia |

cpt fe- 196℃~ 120℃ |

|

pctfe-196℃~ 125℃ |

|

|

external surface roughness:ra≤0.8μm以及≤0.4μm |

|

|

external surface roughness:≤ra0.6μm以及≤ra0.25μm |

|