pipe fittings, valves, aseptic diaphragm valves, aseptic tank bottom valves and other high-end products

pipe fittings, valves, aseptic diaphragm valves, aseptic tank bottom valves and other high-end products

high pressure ball valves are applicable with pipelines in different working conditions of pressure class 150~2500lb and temperature range-28~300℃

in petroleum,chemical and thermal power industries,with special consideration on its safety and resistance to harsh environments.

the applicable media include water,steam,oil,nitric acid,acetic acid,urea and other corrosive and strongly oxidizing media.

allowed operations include manual,pneumatic,electric,hydraulic and pneumatic/hydraulic operations,etc.

1.when the stagnant pressure in the cavity of high-pressure ball valve exceeds the pre-tightening force of the spring,the valve seat retreats away

from the ball and pressure will be automatically relieved,after which the valve seat automatically resets.

2.in the event of a fire or abnormal temperature rise,the sealmaybe burnt or softened.to stop the fire from spreading,resort to the pressure of spring

and medium;the spherical surface of the support ring and the sphere can thus form a metal-to-metal contact to achieve a temporary sealing effect, in accordance with the provisions of api6fa.

3.the gland ofhigh-pressure ball valve is sealed with ptfr packing and o-ring double sealing ring,especially suitable for gases.the packing material is packed in the packing disc,and

the new sf type self lubricating sliding bushing with low friction system can be used at any time to reduce the operating torque.

4.conform with iso5211 platform design standards.no need to connect brackets and bushings,making it easier to install the actuator.

5. 2000psi 3-pcs ball valve adopts iso5211 platform design standards.no need to connect brackets and bushings,making it easier to install the actuator.it could be connected by means

of socket welding,thread,butt welding,flange,etc.

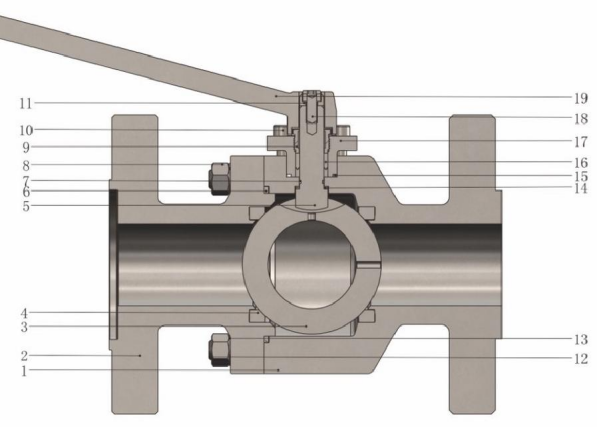

|

number |

name |

material |

|

1 |

valve body |

ss/hc/t |

|

2 |

valve cap |

ss/hc/ti |

|

3 |

ball core |

ss/hc/ti |

|

4 |

body seal |

ptfe |

|

5 |

valve stem |

ss/hc/ti |

|

6 |

cap seal |

ptfe |

|

7 |

o-type gasket |

fkm |

|

8 |

nut |

304 |

|

9 |

press nail |

304 |

|

number |

name |

material |

|

10 |

screw |

304 |

|

11 |

gland |

304 |

|

12 |

bolt |

304 |

|

13 |

spring washer |

304 |

|

14 |

spacer |

ptfe |

|

15 |

spacer |

ptfe |

|

16 |

v-seal components |

ptfe |

|

17 |

gland |

ss/hc/ti |

|

18 |

screw |

304 |

|

19 |

pull handle |

304 |

note:the material of each part may be different under dlifferent working conditions.the specific materialshall prevall

|

technical parameters: |

|

|

actuation |

stainless steel stem,aluminum pneumatic actuator(single/double acting),electricactuator |

|

size |

dn15-dn100 |

|

body |

flange body |

|

fluid-contacting surface |

ss/hc/ti |

|

non-fluid-contacting surface |

ss |

|

connection |

flange |

|

operation pressure |

dn10-dn100 pn40~pn160 bar |

|

operation temperature |

dependent on seal materials |

|

fluid-contacting surface roughness:≤ra0.6μm ≤ra0.25μm |

|

|

external surface roughness:ra≤0.8μm ≤0.4μm |

|