pipe fittings, valves, aseptic diaphragm valves, aseptic tank bottom valves and other high-end products

pipe fittings, valves, aseptic diaphragm valves, aseptic tank bottom valves and other high-end products

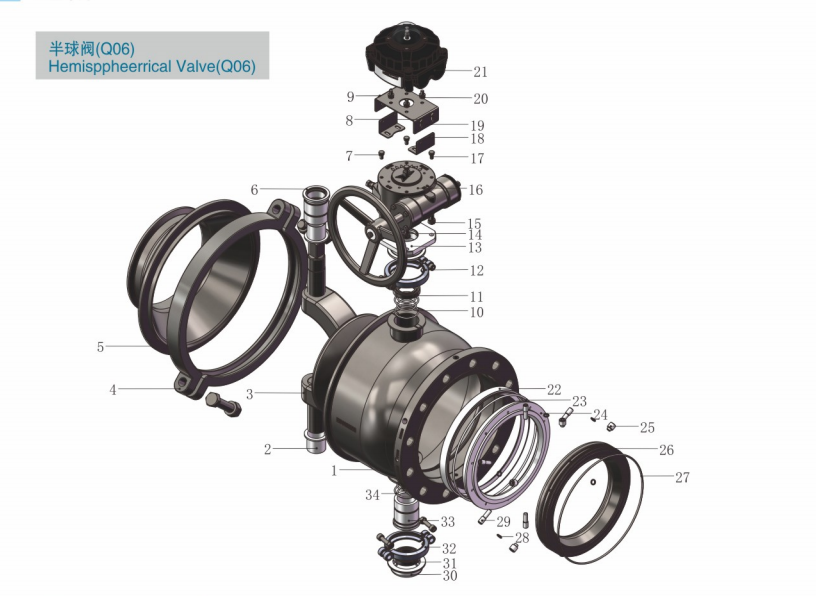

hemisppheerrical valve,a new type of quick-opening and closing valve,is the most popular and efficient valve in the pneumatic ash conveying system of coal burning power plants.

it is mainly used in the feeding of dryashand dry powder in pneumatic conveying systems in the fields ofelectric power,metallurgy,food,chemical and pharmaceutical industries.

hemisppheerrical valve when the valve is opened or closed,the distance between ball core and silicon seal remains at 1mm,ensuring there is no contact or friction between ball core and silicon seal,decreasing wearing.hemisppheerrical valve is pneumatically actuated by a fully enclosed rotary rod.the way the rod directly actuates the valve effectively stops ashes coming inside the valve which avoids wearing and leakage caused by ashes.

when the valve is closed,the silicon seal is inflated and closely attaching to the ball core.

they will form a sealing loop,and cuts off the flow of fluids inside the pipe.

otherwise,when the seal is deflated,the ball core is opened and the valve is thus opened.

to meet requirements of different working conditions,different materials and hardening methods will be accordingly selected and applied to the ball core,thus ensuring its the close contact with silicon seal.

the silicon seal is made of a special material,known for its long service life and resistance to high temperature,corrosion,wearing and aging.

when the valve is opened,the inletis fully opened without any blockage.

flexible to open and shut.when opening or shutting,the distance between ball core and silicon seal remains at 0.8-1.5mm,without direct contact or strong friction.flexible and reliable operation.long service life.when the valve is opened,the inlet is fully opened without any blockage,which avoids the direct contact between fluid and ball core.

perfectly sealed.hemisppheerrical valve is sealed by inflatable silicon seal,which has a great sealing performance.when the valve is closed,the silicon seal is inflated,closing attaching to the ball core and forming a sealing loop,thus effectively cutting off the fluids inside the pipe.

strict requirements for materials.professional techniques for production.the most fundamental technology of hemisppheerrical valve lies in the ball core.

to meet requirements of different working conditions,different materials will be selected to make the ball core resistant to wearing and flushing of fluids.

its smooth and hard surface ensures the close contact between the ball core and silicon seal.sealing can thus be effected.

automatic control and reliable operation.the pneumatic actuator is driven by a fully enclosed rotary rod,with rotary output,reliable performance and large output torque,which can meet requirements in harsh working conditions.

|

number |

name |

material |

|

1 |

valve body |

ss/hc/ti |

|

2 |

guide sleeve |

ptfe |

|

3 |

ball core |

ss/hc/ti |

|

4 |

high pressure clamp |

cf8 |

|

5 |

valve cover |

ss/hc/ti |

|

6 |

guide sleeve |

ptfe |

|

7 |

spring washe |

304 |

|

8 |

spring washer |

304 |

|

9 |

screw |

304 |

|

10 |

o-ring |

fkm |

|

11 |

ball bering |

304 |

|

12 |

high pressure clam |

cf8 |

|

13 |

bracket |

304 |

|

14 |

spring washer |

304 |

|

15 |

screw |

304 |

|

16 |

turbine handle |

cf8 |

|

17 |

screw |

304 |

|

18 |

bracket |

304 |

|

19 |

bracket |

304 |

|

20 |

screw |

304 |

|

21 |

explosion proof transponde |

al |

|

22 |

件stopper |

ss/hc/ti |

|

23 |

o-ring |

fkm |

|

24 |

sealing element |

vmq |

|

25 |

external screw plug |

304 |

|

26 |

slider |

ss/hc/ti |

|

27 |

o-ring |

fkm |

|

28 |

extenal screw plu |

304 |

|

29 |

screw |

304 |

|

30 |

堵头plug |

304 |

|

31 |

ball bering |

304 |

|

32 |

high pressure clamp |

cf8 |

|

33 |

guide sleeve |

ptfe |

|

34 |

oo-ring |

fkm |

|

technicalparameters: |

|

|

actuatior |

turbine stem,pneumatic actuator (single/double acting),electric actuator |

|

size |

dn50-dn300 |

|

body |

one-channel body,tank bottom type body,v-shaped regulating body |

|

fluid-contacting surface |

astm a182 :316l astm b574:c276/c22 gb/t 2965 ta2 ta10 |

|

non-fluid-contacting surface |

astm a182304 |

|

connectio |

welded,clamped,flange |

|

operation pressure |

dn50-dn300 pn16bar |

|

operation temperature |

dependent on seal materials |

|

seal materia |

epdm seal:-10~ 120 ℃ |

|

vmq seal:-10~ 150 ℃ |

|

|

fkm seal:-10~ 180℃ |

|

|

fluid-contacting surface roughness:≤ra0.6μm ≤ra0.25μm |

|

|

optional accessory (pneumatic) |

solenoid valve,limit switch,electrical positioner,handwheel clutch,air filter pressure relief pressure options for explosion-proof levels:ex d il bt4 exd|i ct6 exia il ct6 |