pipe fittings, valves, aseptic diaphragm valves, aseptic tank bottom valves and other high-end products

pipe fittings, valves, aseptic diaphragm valves, aseptic tank bottom valves and other high-end products

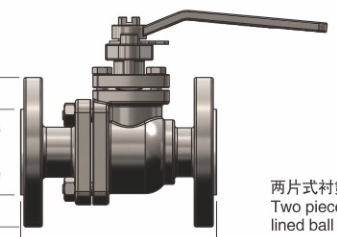

fluorine-lined ball valve is designated for controlling the flow of highly corrosive media,with a structure of floating ball and straight- through body.the valve is connected by means of flange.the body is made of carbon steel lined with fluorine plastic inside.the ball core and stem are fully integrated,made of metal and wrapped with fluorine plastic.fluorine-lined ball valve is of great value in terms of its good corrosion resistance and sealing,flexible and fast opening and closing,aesthetic design,great hardness and durability.it is the most widely used corrosion-resistant valve in the modern chemical process.

the ball valve,lined with fluorine plastic,has a joint structure of ball and stem and a unique elastic lip sealing structure.it is not only credited with functions of traditional ball valves,but also with great performance in large pressure differences and temperature changes due to its high sealing performance and low operating torque.it can be used for switching or regulating flows.

1.smallfluid resistance.straight structure;basically no flow resistance.

2.compact and reliable.two ptfe sealing seats are installed inside to ensure the

valve is fully sealed.the valve can be widely used in vacuum systems.

3.simple structure.easy to maintain.the seals are movable,making it convenient to disassemble and replace.

4.when the valve is fully opened or closed,the ball and seals are isolated from media.

5.great sealing performance.zero leakage.

suitable for the transfer of liquid and gas media (including steam)in industrial pipelines,including concentrations of aqua regia,sulfuric acid,hydrochloric acid,organic acids,strong acids and strong oxidants at -50℃~150℃.pfa-lined ball valves can even be used in pipelines with various concentrations of strong alkali organic solvents and other corrosive gas or liquid media.

|

size |

d |

c |

e |

n-∅h |

l |

|

|

dn10 |

1/2" |

90 |

60 |

41 |

4-∅14 |

130 |

|

dn15 |

3/4" |

95 |

65 |

45 |

4-∅14 |

130 |

|

dn20 |

/ |

105 |

75 |

55 |

4-∅14 |

140 |

|

dn25 |

1" |

115 |

85 |

65 |

4-∅14 |

150 |

|

dn32 |

11/4" |

135 |

100 |

78 |

4-∅18 |

165 |

|

dn40 |

11/2" |

145 |

110 |

85 |

4-∅18 |

180 |

|

dn50 |

2" |

160 |

125 |

100 |

4-∅18 |

200 |

|

dn65 |

21/21 |

180 |

145 |

120 |

4-∅18 |

220 |

|

dn80 |

3.5" |

195 |

160 |

135 |

8-∅18 |

250 |

|

dn100 |

4” |

215 |

180 |

155 |

8-∅18 |

280 |

|

dn125 |

5" |

245 |

210 |

185 |

8-∅18 |

320 |

|

dn150 |

6" |

280 |

240 |

210 |

8-∅23 |

360 |

|

dn200 |

8" |

335 |

295 |

265 |

8-∅23 |

400 |

|

dn250 |

10° |

405 |

355 |

320 |

12-∅26 |

450 |

|

technical parameters: |

|

|

actuation |

stainless steel stem,turbine stem,aluminum pneumatic actuator (single/double acting),electric actuator |

|

size |

dn10-dn250 |

|

body |

2-pcs valve body |

|

fluid-contacting surface |

astm a351 cf3m/cf8 fluorine lined plastic |

|

non-fluid-contacting surface |

astm cf8/304 |

|

connection |

flange |

|

operation pressure |

pn1.0~1.6mpa |

|

operation temperature |

-80℃~ 200℃ |

|

lining material |

ptfe(f4)、fep(f46)、pfa、po |

|

flange standard |

gb/t9113.1、jb/t79.1、asmeb16.9 |

|

pneumatic accessory |

solenoid valve,limit switch,electrical positioner,handwheel clutch,air filter pressure relief press options for explosion-proof levels:exd ‖ bt4 exd ‖ ct6 exia ‖ ct6 |