pipe fittings, valves, aseptic diaphragm valves, aseptic tank bottom valves and other high-end products

pipe fittings, valves, aseptic diaphragm valves, aseptic tank bottom valves and other high-end products

widely applied in pharmaceutical,biological and semi-conductor engineering industries to control feeding in the feeding mouth of reactors.

to transfer the fluids with viscous or particulate matters.

easy and quick to assemble and disassemble the valve,making it easier to be opened and maintained,decreasing the production downtime.compact structure.

the drainage outlet can be washed cyclically.support cip and sip inside the cavity.

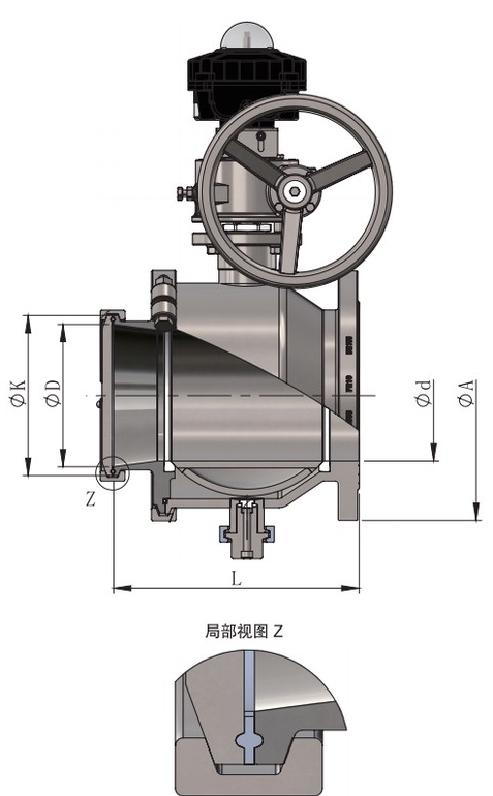

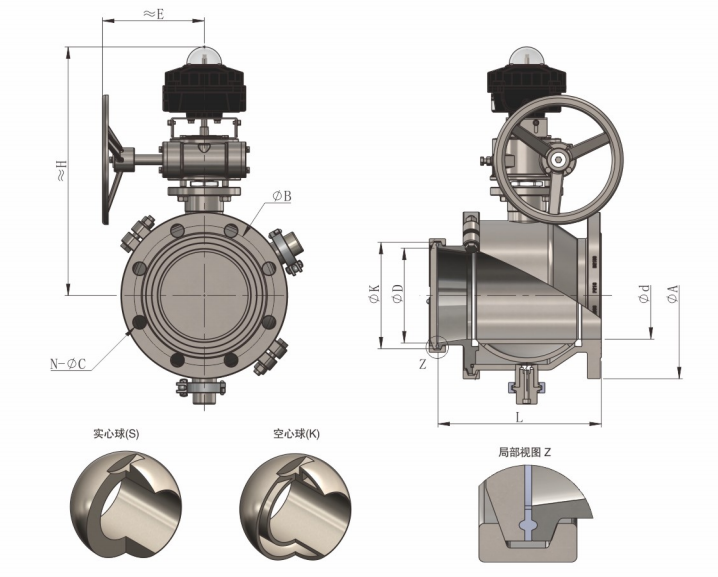

1.blow-out proof stem adds safety and reliability to the full extent.

2.thickened stem packing;v-shaped stacking design;adjustable self-compensating gland.

3.anti-static stems are also available for specific working conditions.

4. 3a/iso sanitary clamp.structure is reinforced.

5.no residue design.

6.the fluid-contacting surface is self-draining and sanitary.

7.equipped with a dust cap(with a handle).after feeding is completed, close the dustcap immediately to prevent any foreign matter falling into the reactor.

8.a manual turbine is available,significantly decreasing the operating torque.

9.equipped with a explosion-proof transponder. according to on-site environment,explosion suppression type or intrinsically safe explosion-proof type can be wiselyprovided.

all sealing materials contacting with fluids are reinforced ptfe, in accordance withfda177.1550 and gmp standards.

10.support cip(clean-in-place) and sip(sterilization-in-place).

|

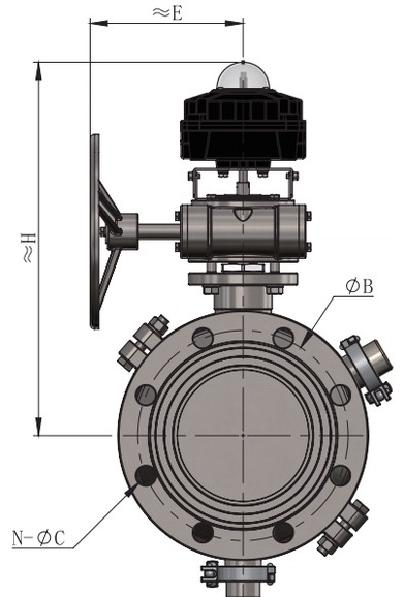

nominal diameter |

nominal pressure pn10 |

nominal pressure pn16 |

l |

h |

e |

d |

k*d |

||||||

|

a |

b |

n-oc |

a |

b |

n-oc |

din1850 |

iso |

3a/bpe |

|||||

|

dn80 |

/ |

/ |

/ |

200 |

160 |

8-18 |

168 |

360 |

132 |

80 |

106*81 |

106*85 |

106*72.9 |

|

dn100 |

/ |

/ |

/ |

220 |

180 |

8-18 |

195 |

374 |

32 |

100 |

119*100 |

119*97.4 |

119*97.4 |

|

dn150*100*150 |

/ |

/ |

/ |

220 |

180 |

8-18 |

186 |

331 |

32 |

100 |

183*150 |

183*163 |

166.8*146.8 |

|

dn125 |

/ |

/ |

/ |

250 |

210 |

8-18 |

220 |

393 |

132 |

125 |

155*125 |

155*123 |

/ |

|

dn150*125*150 |

/ |

/ |

/ |

250 |

210 |

8-18 |

220 |

393 |

132 |

125 |

183*150 |

166.8*146.8 |

166.8*146.8 |

|

dn150 |

/ |

/ |

/ |

285 |

240 |

8-22 |

254 |

426 |

175 |

150 |

183*150 |

166.8*146.8 |

166.8*146.8 |

|

dn200*150*150 |

340 |

295 |

8-22 |

340 |

295 |

12-22 |

254 |

||||||

|

dn250*150*150 |

395 |

350 |

12-22 |

405 |

355 |

12-26 |

254 |

||||||

|

dn300*150*150 |

445 |

400 |

12-22 |

460 |

410 |

12-26 |

254 |

||||||

|

dn200*150*200 |

340 |

295 |

8-22 |

340 |

295 |

12-22 |

254 |

426 |

175 |

150 |

233.5*200 |

233.5*213.8 |

233.5*213.8 |

|

dn250*150*200 |

395 |

350 |

2-22 |

405 |

355 |

12-26 |

254 |

||||||

|

dn300*150*200 |

445 |

400 |

12-22 |

460 |

410 |

12-26 |

254 |

||||||

|

dn200 |

340 |

295 |

8-22 |

340 |

295 |

12-22 |

330 |

472 |

175 |

200 |

|||

|

dn250*200*200 |

395 |

350 |

12-22 |

405 |

355 |

12-26 |

312 |

||||||

|

dn300*200*200 |

445 |

400 |

12-22 |

460 |

410 |

12-26 |

312 |

||||||

|

technicalparameters |

|

|

actuatior |

turbine stem,aluminum pneumatic actuator(single/double acting),electric actuator |

|

size |

dn80-dn300 |

|

body |

feeding valve body |

|

fluid-contacting surface |

ss/hc/ti |

|

non-fluid-contacting surface |

ss |

|

connection |

flange weld |

|

operation pressure |

dn80-dn300 pn16bar~pn63bar |

|

operation temperature

|

dependent on sealmaterials |

|

fluid-contacting surface roughness:≤ra0.6μm≤ra0.25μm |

|

|

external surface roughness:ra≤0.8 μm以及≤0.4μm |

|