pipe fittings, valves, aseptic diaphragm valves, aseptic tank bottom valves and other high-end products

pipe fittings, valves, aseptic diaphragm valves, aseptic tank bottom valves and other high-end products

to be applied in pharmaceutical industries and chemical equipment:pressure vessel,seawater treatment equipment,seawater heat exchanger,papermaking machine,sulfuric acid/nitric acid equipment.

to be applied in food industry:soy sauce,cooking wine,salt equipment.

to be used for controlling the flow of fluids with viscous or particulate matters;available with automatic or manual actuationmanners.

products are mechanically polished until the surface is smooth and clean.media can be completely drained,leaving no risk of contamination.

blow-out proof stem adds safety and reliability to the full extent.

1.thickened stem packing;v-shaped stacking design;adjustable self-compensating gland.

2.the sealing point is above the thread of valve cap,so media won't accumulate in the clearance of threads.

3.all sealing materials contacting with fluids are reinforced ptfe,in accordance with fda177.1550 and gmp standards.

4.support cip(clean-in-place) and sip (sterilization-in-place).

|

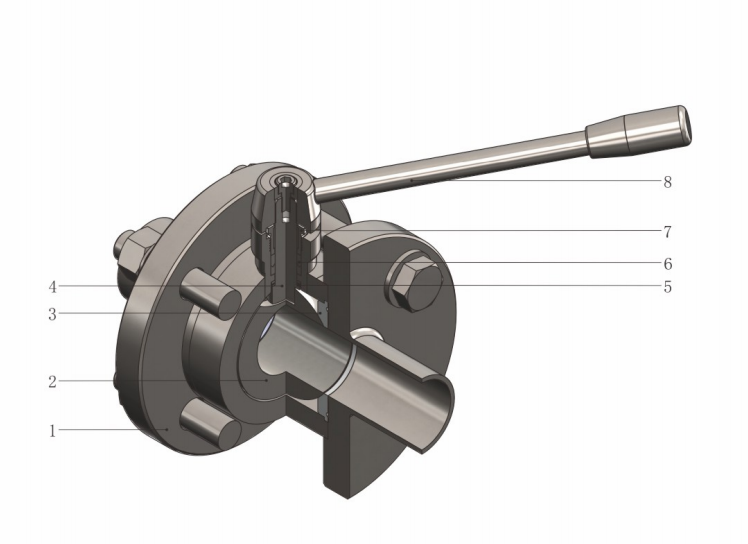

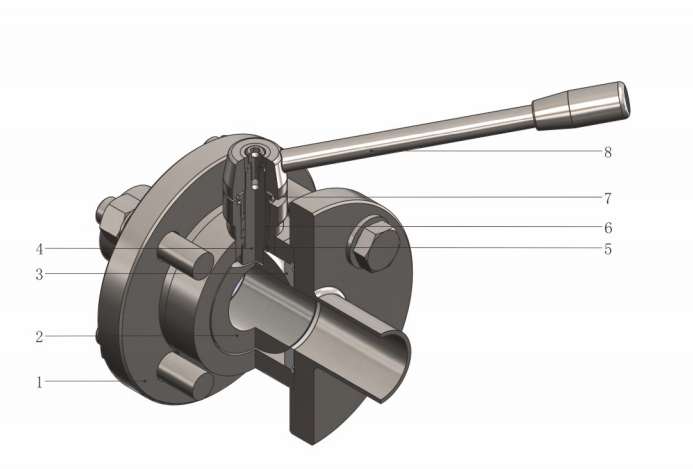

number |

name |

material |

|

1 |

valve body |

ss/hc/ti |

|

2 |

ball core |

ss/hc/ti |

|

3 |

body seal |

ptfe |

|

4 |

valve stem |

ss/hc/ti |

|

5 |

gasket |

304 |

|

6 |

v-seal components |

ptfe |

|

7 |

press nail |

304 |

|

8 |

handle |

304 |

|

technical parameters: |

|

|

actuation |

stainless steel stem,aluminum pneumatic actuator(single/double acting),electricactuator |

|

size |

dn10-dn100 |

|

body |

45° -switching straight body |

|

fluid-contacting surface |

ss/hc/t |

|

non-fluid-contacting surface |

ss |

|

connection |

wafer |

|

operation pressure |

dn10-dn100 pn16bar |

|

operation temperature |

dependent on sealmaterials |

|

fluid-contacting surface roughness:≤ra0.6μm≤ra0.25μm |

|

|

external surface roughness:ra≤0.8 μm以及≤0.4μm |

|