pipe fittings, valves, aseptic diaphragm valves, aseptic tank bottom valves and other high-end products

pipe fittings, valves, aseptic diaphragm valves, aseptic tank bottom valves and other high-end products

nuomeng is a r&d enterprise that has an expertise in the development of specail valves.relying on a strong technical background,with the

great effort of the original special valve team,we develop special material valves(hastelloy hc-276/c22/b2,monel,inconel,titanium,alloy

ta2/ta9/ta10,dual-phase steel 2205/2507,904l,20 alloy,titanium,zirconium,nickel,tantalum,etc).to meet user needs.we employ special

material valve molding,special material silica sol precision casting,imported special material bars,cnc finishing services for the entire production

chain.the special valves are intended to tackle harsh working conditions according to customer needs,replacing imported products to some extent,

and we have achieved good pragresses and obtained a number f patents because of the product.it is also recognized as a breaktrhough,eliminating

defects of traditional valves,increasing service life and improving high temperature sealing performance.

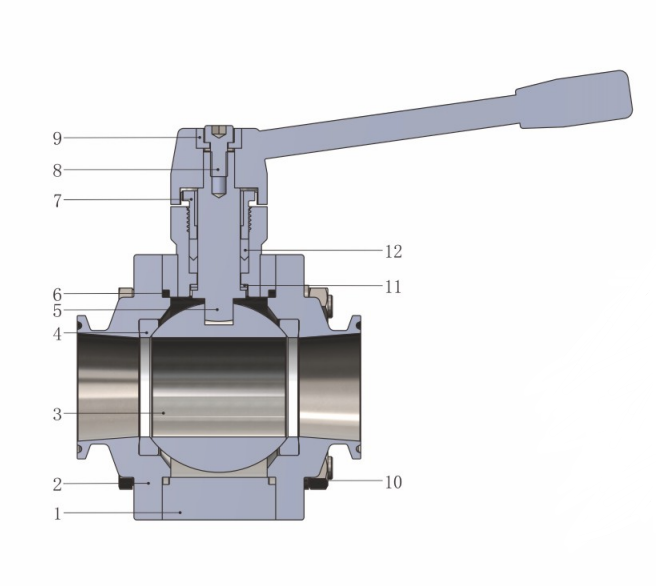

3-pcs ball valves are flexible to set up and easy to be maintained online or offline,which significantly minimizes the roduction downtime due to valve or pipeline maintenance.

during maintenance,it is not necessary to disassemble the actuator or joint component from the valve.when themaintenance is completed,it is also convenient to re-amount the valve or actuatorcomponents;no calibration is needed.

integral mounting surface conforms with iso 5211 standards and assists the correct installation of actuator,ensuring the actuator is not able to move when rotating at high speed or loading for a long time.

when the valve is working at its highest allowable working pressure,the actuator can still be safely and conveniently removed and maintained.

sanitary ball valves are processed through fine cnc machining.

allfluid-contacting surtaces are delicately polished to meet the standards that the internal surface roughness shall meet ra≤0.8 μm.

orwe can meet ra≤0.4 μm or even ra≤0.25 μm according to your requirements.

the external surfaceroughness of forged products can meet ra≤0.8 μm or ra≤0.4 μ m.

to prevent contamination,all components,after processing,shall be put in an ultrasonic cleaning sink and cleaned with

special solutions to remove oil and grease.

assembly and calibration shall be carried out in a designated cleaning room,so as to make sure that every ball valve can be used in a sanitary system.

valve bodies and caps are all forged.in case of specific working conditions,special materials, such as ss/hc/ti,will also beapplied.

standard tfm600 seals are compatible with most operating conditions (-60℃~ 150℃).

pob seal is also available as an option,which is also compatible with many operating conditions (-10℃~ 210℃).

ek seal is also available for other operating conditions (-20°c~ 250℃).

|

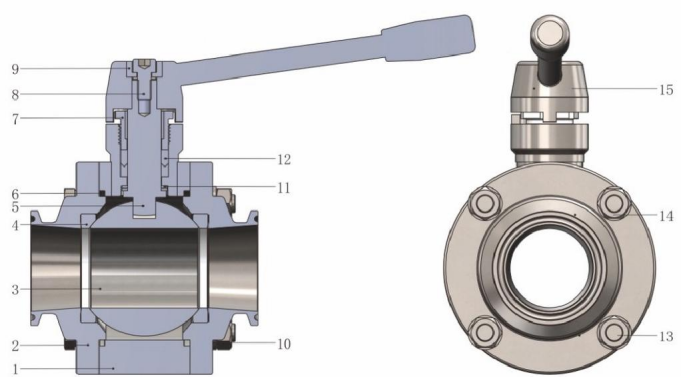

number |

name |

material |

|

1 |

valve body |

ss/hc/ti |

|

2 |

valve cap |

ss/hc/ti |

|

3 |

ball core |

ss/hc/ti |

|

4 |

body seal |

ptfe |

|

5 |

valve stem |

ss/hc/ti |

|

6 |

cap seal |

ptfe |

|

7 |

press nail |

304 |

|

8 |

screw |

304 |

|

number |

name |

material |

|

9 |

cover plate |

304 |

|

10 |

spring washe |

304 |

|

11 |

ring |

ptfe |

|

12 |

v-seal components |

ptfe |

|

13 |

hexagon screw |

304 |

|

14 |

nut |

304 |

|

15 |

handle |

304 |

note:the material of each part may be different under different working conditions.the specific materialshall prevail.

|

technical parameters: |

|

|

actuation |

stem,turbine,aluminum pneumatic actuator(single/double acting),electric actuator |

|

size |

dn10-dn300 1/2"-12" |

|

body |

one-channel body,tank bottom type body,3-way square body,4-way square body |

|

ball core |

straight type,t shape,l shape |

|

fluid-contacting surface |

hc-276/c22/b2,monel,inconel,ta2/ta9/ta10/gr5/gr2/gr3 duplex 2205/2507 /904,20 alloy,zirconium titaniumnickel tantalum |

|

non-fluid-contacting surface |

astmss304 |

|

connection |

welded,clamped,flange,female thread,etc |

|

operation pressure |

pn1.0-4.0mpa class150-300lb |

|

operation temperature |

dependent on seal materials |

|

seal material |

medium temperature(-60~ 150 ℃):tfm1600 seal |

|

high temperature(-10~ 210 ℃):pob sea |

|

|

fluid-contacting surface roughness:≤ra0.4μm ≤ra0.25 μm |

|

|

accessory(pneumatic) |

handwheel clutch(only available for aluminum pneumatic actuators) |

|

optional accessory (transponder) |

apl210n:ip67 2-npt1/2" |

|

vls1000:exd ⅱ|bt6 ip67 2-npt3/4" |

|

|

vls1000s:exdi|ct6 ip67 2-npt3/4" |

|

|

vls1121:exia ||ct6 ip67 2-npt3/4" |

|

|

vls1221:exiallct6 p&f ip67 dc 8v 2-npt3/4" |

|

|

optional accessory solenoid valve) |

solenoid valve air filter pressure-relief valve(plastic connector pu air pipe ac220v ac110v ac380 |

|

explosion-proof solenoid valve air filter pressure-relief valve(pipe ferrule stainless steel air pipe)dc12v dc24v |

|

|

asco explosion-proof solenoid valve air filter pressure-relief valve(pipe ferrule stainless steelair pipe)dc12v dc24v |

|

|

optional accessory:1500 intelligent positioner:set input signal at 4-20ma and output signal at 4-20ma dc 24v |

|

|

optional accessory:n6000 intelligent positioner:set input signal at 4-20ma and output signal at 4-20ma dc 24v explosion-proof level:ex ia iic t4/t6 ga |

|